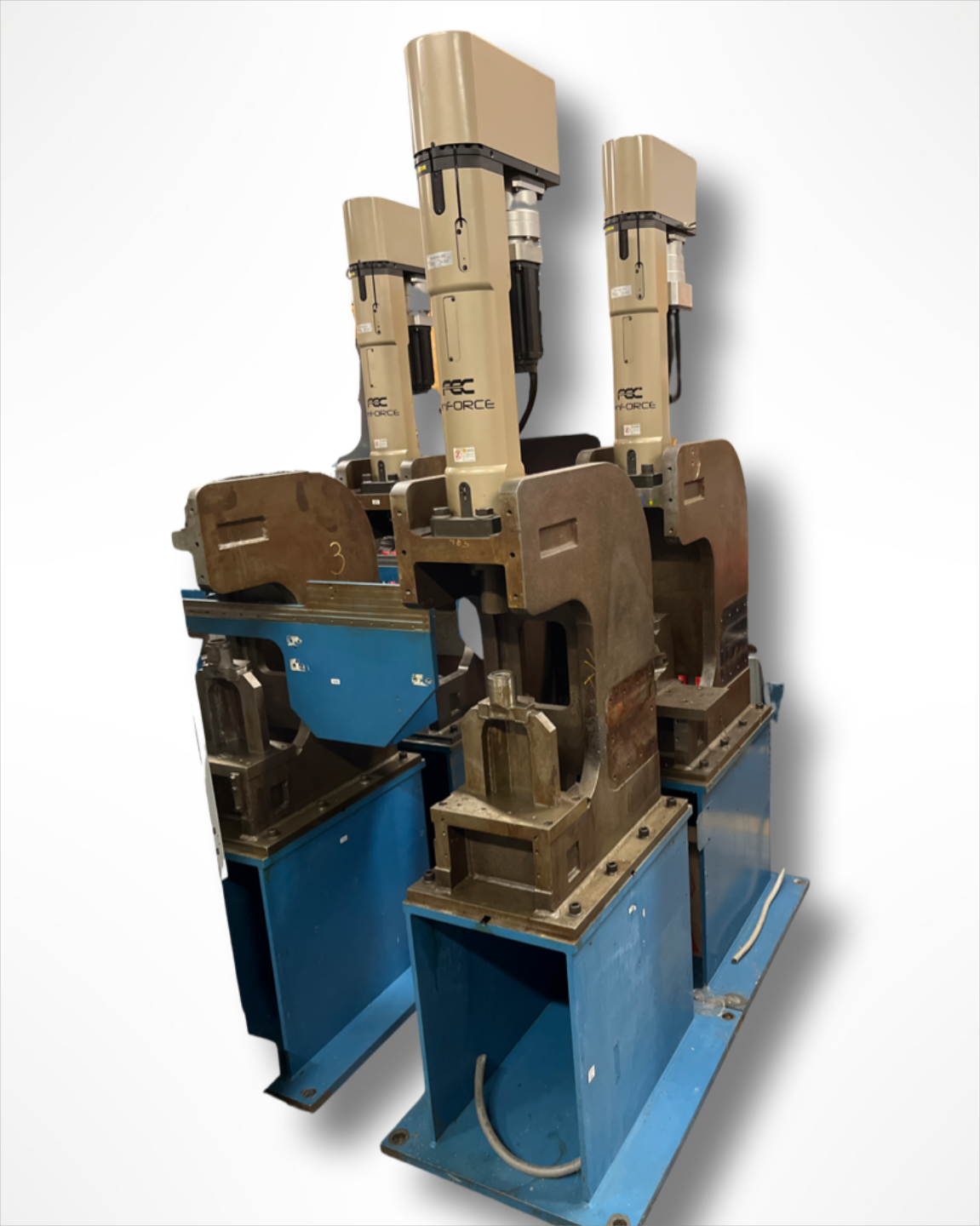

FEC EnForce Servo Press System

In-Store Only

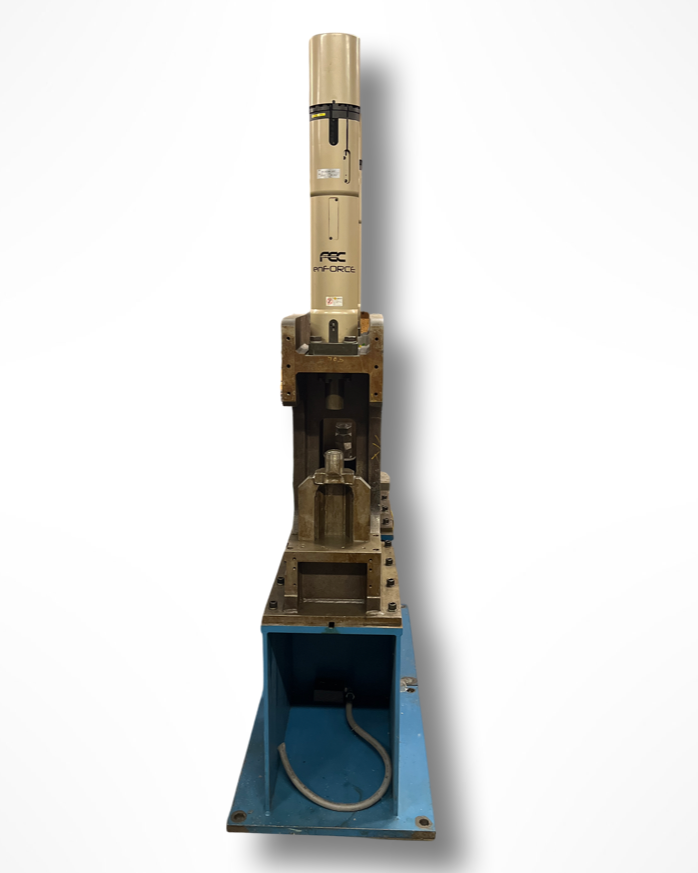

Standard stroke for both Fitting and Bonding presses is 200mm.

FITTING TYPE (Holding time generally < 1sec)

Part Number: DPS-801R4H-20FB

- Max. Load(kN / Tonne) - 80.0 /8.16

- Continuous Load(kN / Tonne) - 18.0 / 1.83

- Max. Speed(mm / sec) - 120

- Length(mm / in) - 817 / 32.2

- Width(mm / in) - 135 / 5.3

- Height(mm / in) - 375 / 14.8

- Weight(kg / lbs) - 98/216

Part Number: DPS-102R5-20FB

- Max. Load(kN / Tonne) - 100.0 / 10.20

- Continuous Load(kN / Tonne) - 0032.0 / 3.26

- Max. Speed(mm / sec) - 133

- Length(mm / in) - 817 / 32.2

- Width(mm / in) - 135 / 5.3

- Height(mm / in) - 375 / 14.8

- Weight(kg / lbs) - 110 / 243

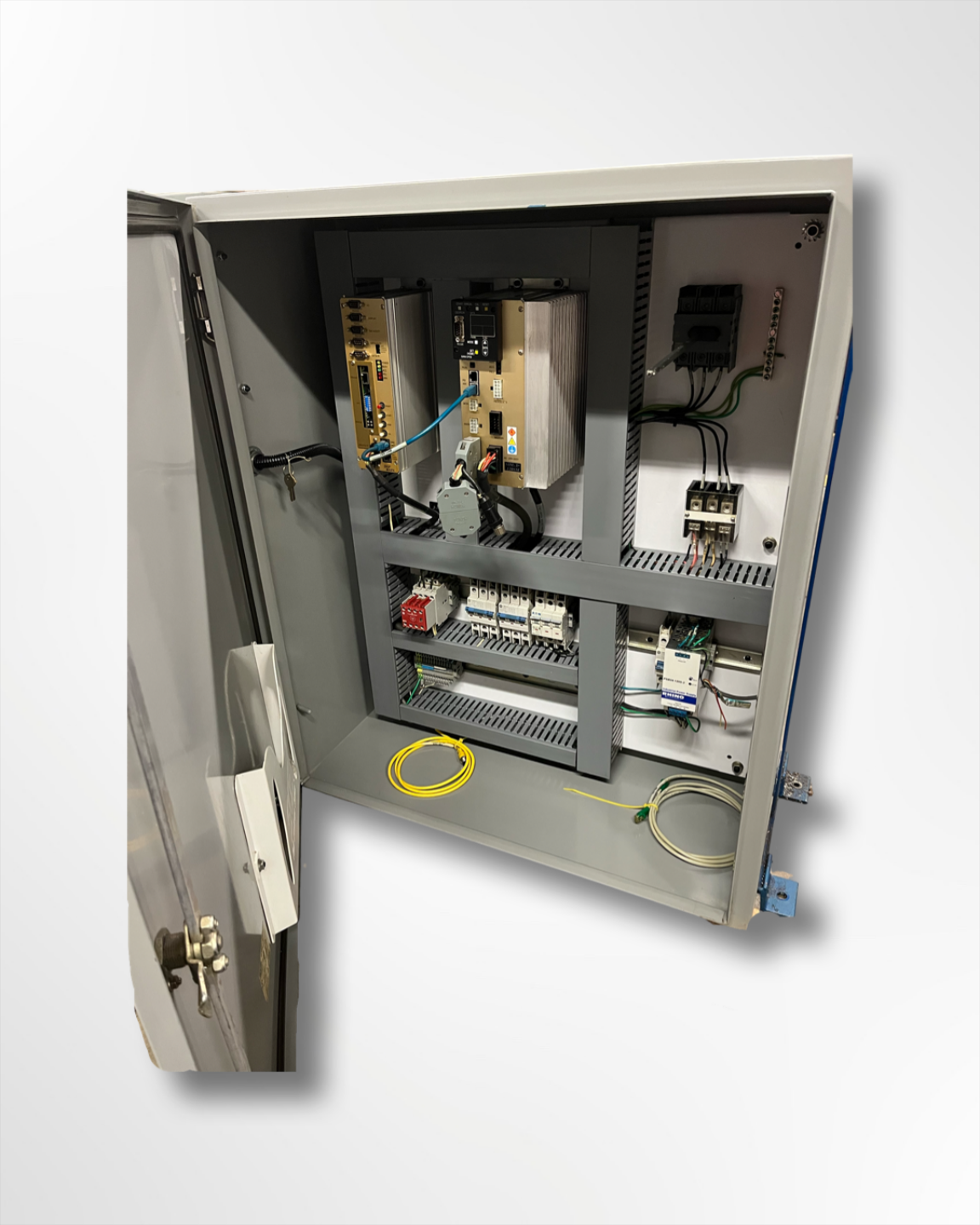

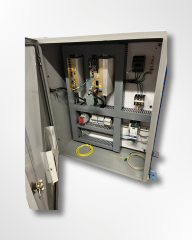

Included Controller

Three controller models cover the full range of press sizes. As a result of miniaturized circuit technology, the compact units maintain a maximum width of 123.5mm (largest model) in spite of the built in power source and servo amplifier. All 3 controllers are back panel mountable and feature the following:

- Isolated Gate Bipolar Technology (IGBT).

- Fully Digital System (eliminates analog potentiometers).

- 32 different work parameters (part programs) that can be stored into Flash ROM. No battery backup required.

- External communication is available through (2) RS-485 ports. Connecting a group of up to 31 press controllers is also possible through this port when communicating using the DSP User Console Software.

- A hot-swappable Display Module is available for viewing result data and can be used to program individual controllers. The RS-232 version can output single press ASCII data to a serial device.

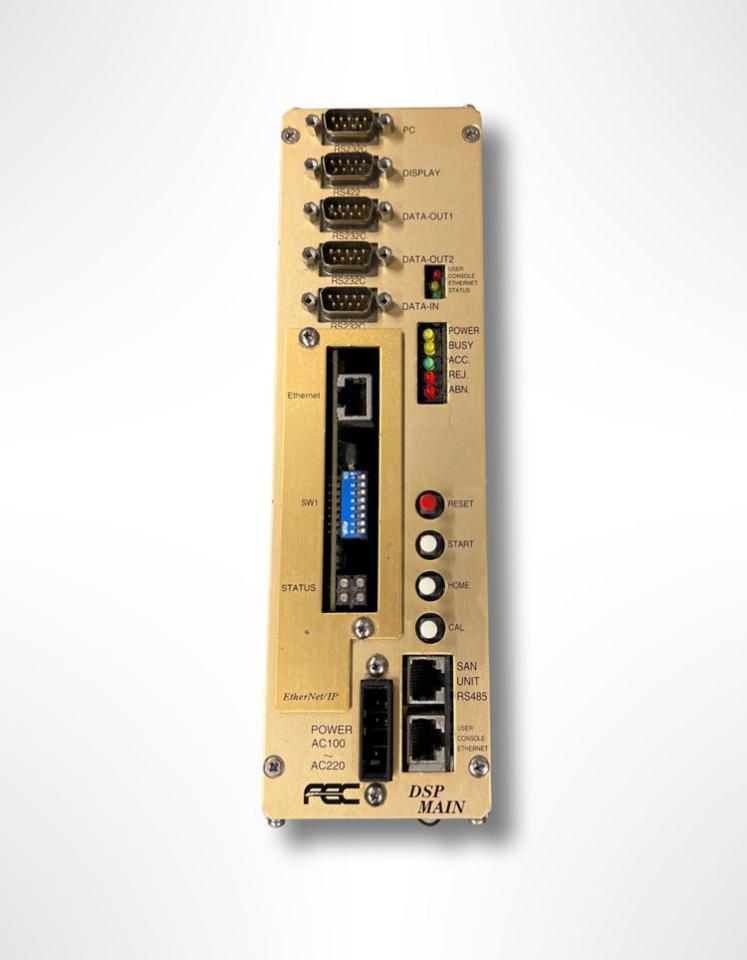

The Main Unit is a complimentary controller device to enhance the DSP1500 capabilities by providing the data communication and sequence control features for single and multiple (up to 31) press applications. The use of the Main Unit reduces valuable engineering, start-up and debug time by allowing full sequencing functionality & press data to be handled independently of an outside controller (PLC). Additionally, all Input / Output functions are assumed by the Main Unit for all connected presses while also allowing use of a multiple of standard Fieldbus Interfaces.

Includes: Ethernet I/P, Allen Bradley Remote I/O® Card, eliminating hard wired I/O thus reducing debug & start-up costs. Additionally, allow transfer of resultant press data across the same communication link as the I/O.

******C-frame presses provide numerous advantages compared to other presses. Some of these benefits include:

Easy access. A C-frame press has three access points to the working area, allowing for easier die maintenance and adjustments. The multiple access points also allow part loading from the left, right, or front of the cell.

Affordable. C-frame presses are more cost-effective than straight-side presses, helping reduce the production line’s overall cost.

Optimized space. With a narrow frame, C-frame presses take up less floor space and provide minimal stroke deflection.

Have a question about this product? Send us a message.

Thanks! Your form has been sent.

Return Policy

We do not accept returns

FEC EnForce Servo Press System